Introduction

In a world driven by innovation, new technology is constantly emerging. We are surrounded by electronics, in fact, you are even engaging with a screen this very moment. Yet, with so many electronic devices everywhere you look, there is a hidden genius that is often overlooked, the circuit card. Every smartphone, every computer, and every gadget are all a result of the intricate process of circuit card assembly, the backbone of modern technology.

Circuit card assembly (CCA), sometimes known as printed circuit board assembly (PCBA), refers to the process of assembling electronic components onto a circuit card. It often consists of five key stages.

Five key stages of Circuit Card assembly

Component placement

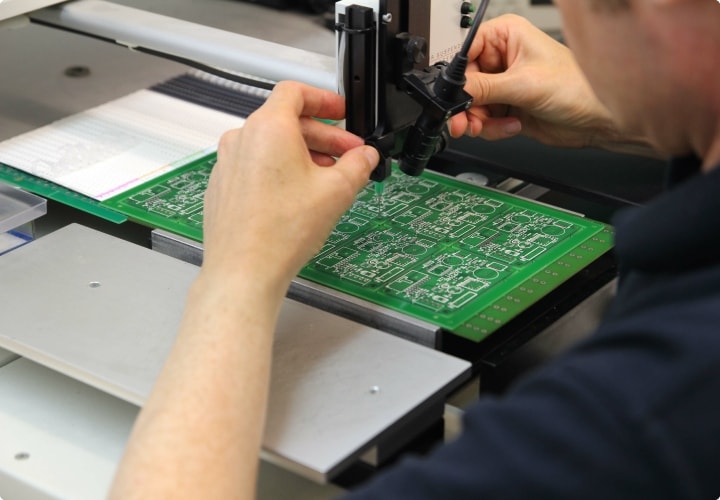

Components are intricately placed onto the circuit card, following a designated design layout. It is crucial that this design layout is followed closely because the

specific placement of each component forms the pathways for electrical connections, which are vital for the functionality of an electronic device. This stage can be completed manually or with the assistance of automated equipment, such as pick-and-place machines.

Soldering

When in position, the components are soldered onto the circuit card to establish electrical connections and to ensure they are securely held in place. Soldering can be done using a variety of methods, including surface mount technology (SMT), through-hole technology, and handheld soldering techniques.

Inspection

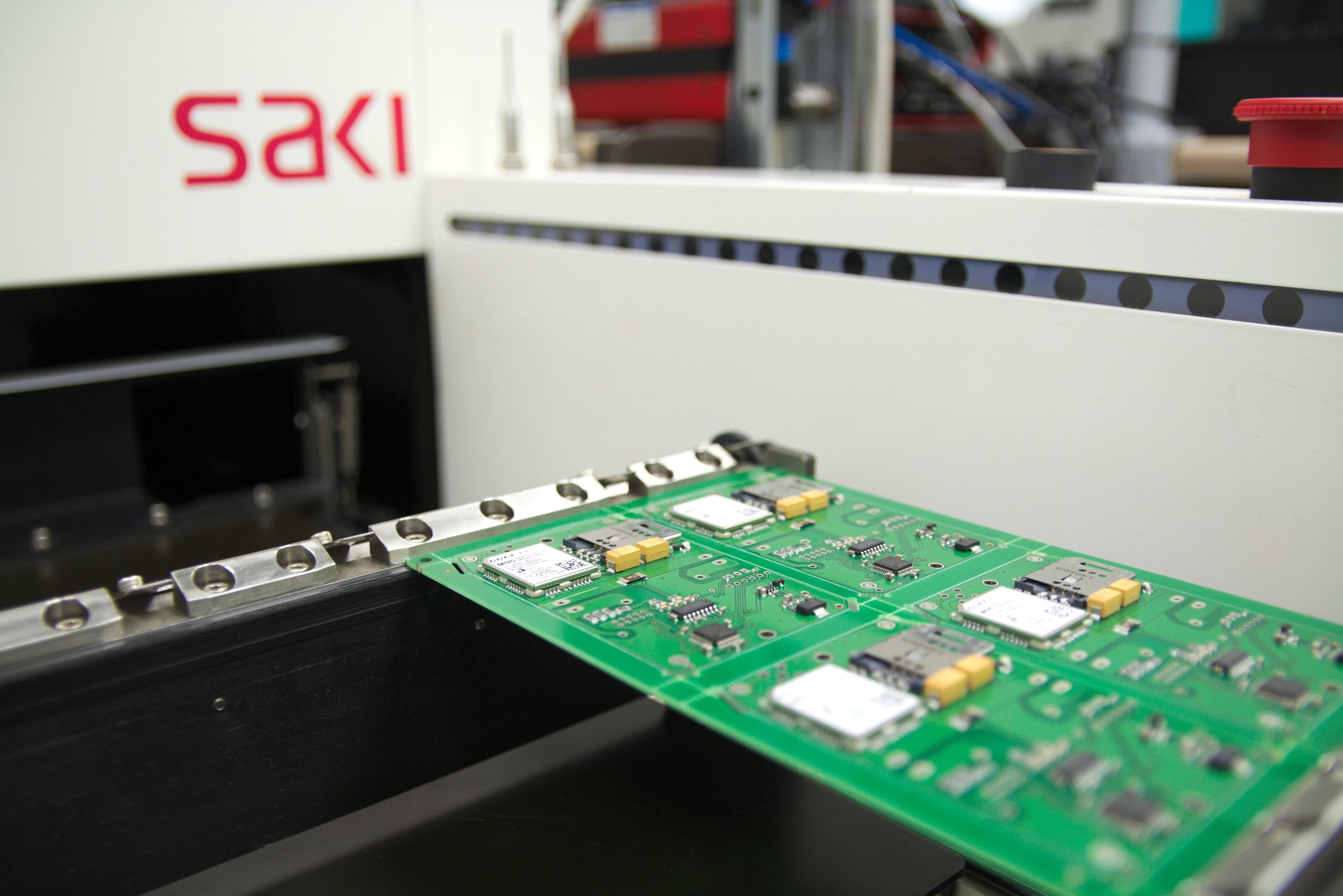

After soldering, the assembled circuit card undergoes inspection to ensure that all the components are free from defects and properly soldered. This stage of circuit card assembly involves both visual inspection and testing using automated methods, such as automated optical inspection. Inspection is crucial for maintaining quality and reliability in the circuit card assembly process.

Testing and quality control

Following soldering and inspection, testing plays a critical role in the circuit card assembly process, ensuring the functionality and performance of the assembled circuit card. This pivotal stage involves verifying whether or not the circuit card meets the desired specifications. Tests encompass checking for reliable connections, detecting open circuits, and confirming proper component values. In order to deliver high-performance electronic devices to customers, it is necessary for the assembled circuit card to pass all conducted tests.

Final assembly

Final assembly is the last step in the circuit card assembly process. Once the circuit card has been tested, it is ready to be integrated into the final electronic device. This involves connecting the circuit card to other components such as displays and power sources, making sure the alignment is correct and all the connections are secure. Once assembled, the device will be ready to use.

Circuit Card Assembly Through Time

Circuit card assembly has evolved rapidly and marks an incredible journey of innovation. With every passing year, circuit cards are shrinking in size, while the technology of the machinery used within the assembly continues to advance.

Circuit Card Evolution

Over the last few decades, we have witnessed a significant shift from hand-soldered components on bulky circuit cards to today’s highly automated, miniaturised assembly processes. In the past, circuit cards used to be extremely large, limiting the size and capabilities of electronic devices. However, advancements in manufacturing techniques and component integration have led to the development of smaller, densely packed circuit cards.

Impact on Technology and Industries

This improved size and reliability of circuit cards have paved the way for the widespread usage of portable gadgets in our world today. It has also led to the development of life-changing medical devices, produced by firms with the ISO 13485 accreditation, such as GSPK Design. These devices include monitoring systems and diagnostic equipment.

Looking Towards the Future

As technological advancements continue at a rapid pace; we can expect to see a continuation of miniaturisation and densely packed circuit cards in the future. This evolution is expected to significantly improve our technological capabilities. Densely packed circuit cards allow for more components, therefore expanding the range of functions that electronic devices can perform. This continual improvement will not only drive innovation, but also enable the development of more advanced and efficient electronic systems.

Conclusion: The Essence of Circuit Card Assembly

In conclusion, circuit card assembly is simply the process of assembling electronic components onto a circuit card. The evolution of circuit card assembly reflects incredible human ingenuity and innovation in electronics. From its modest beginnings, to its current state of advanced automation and miniaturisation, circuit card assembly has been instrumental in shaping today’s digital era. The speed at which these advancements have taken place hints towards a future of even greater developments and sophistication within electronics. Circuit card assembly is responsible for the functionality of every electronic device we see, and its continual advancements are paving the way for a digital future with endless possibilities.

To contact GSPK Design about our Circuit Card Assembly capabilities, press here.